Biomedical Devices & Implants

Historically, the biomedical devices and implants businesses have enjoyed a “Cinderella” relationship with the FDA and international regulatory bodies. In other words, these products have not been subject to the detailed analytical scrutiny typical of drug products. However, today there is an accelerating trend in the regulatory bodies to require thorough leachables, extractables, stability, and shelf life testing with state-of-the-art chemical analysis. It is not unusual for FDA to require identification and quantitation of all analytes. In addition, there is an expectation that the source of each analyte be identified and a safety risk analysis be performed.

Mass Spec Lab is equipped to meet these challenges with the latest in analytical equipment/techniques and years of biomedical implant and materials experience. Mass Spec Lab has added high-resolution UPLC/QTof mass spectrometry and microscopic FTIR to its existing base of analytical expertise. In addition, Mass Spec Lab offers comprehensive biocompatibility assessment and risk analysis services in collaboration with sub-contracting laboratories and consultants.

The following Sub-Specialties within Biomedical Devices & Implants are Served by Mass Spec Lab:

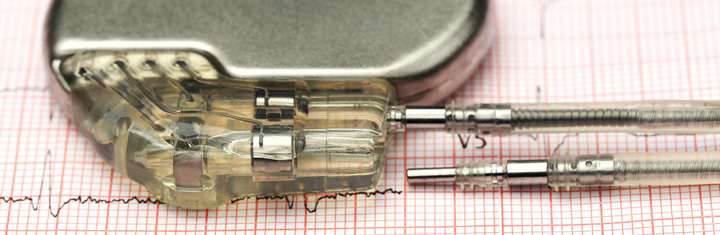

- Devices and Implants: Ophthalmic, Cardiovascular, Urogenital, Neurovascular, Orthopedic

- Biomedical Polymers

- Coatings

- Engineered Tissues

- Drug/Device Combination Products

- Drug Delivery Matrices

- Packaging

Here are some of the applications in Biomedical Devices and Implants where Mass Spec Lab can help:

Extractables & Leachables and stability: Protocols are developed in thorough preliminary consultations with clients. Testing proceeds only after the client fully understands and approves the protocols. Replicate analyses and proper control are included to assure that regulatory reviewers will be completely satisfied with the testing and that there will be a low probability of follow-up questions or deficiency letters. Studies are fully ISO 10993 compliant and performed to US FDA GLP (21 CFR 58) standards.

Raw material screening and material changes: Sometimes a client wants to make a minor change in a material used in a device or implant. On the other hand, perhaps they need to change material supplier or qualify a second source. Mass Spec Lab can devise and execute effective analytical strategies to address these needs to make the changes without the cost of additional clinical testing.

Material formulation selection: Mass Spec Lab can help with analytical strategies to help a client study material formulation options.

Selection of packaging materials: Often a regulatory body will want to know more about the potential for migration of packaging contaminants or additives into an implantable medical device. Mass Spec Lab maintains extensive mass and infra-red spectral libraries of plastics additives to aid in both targeted and non-targeted investigations relating to migratable chemical species in packaging materials. Mass Spec Lab can help in making final packaging decisions.

Biocompatbility and Safety Risk Analyses: Mass Spec Lab has developed a network of biological testing laboratories and consultants in order to provide comprehensive biocompatibility assessments for your biomedical device, implant, or implantable material.