Do you have surfactant related residuals in your product or process?

Do you have a current or potential surfactant problem that we might help you with? Fortunately, it is possible to sensitively monitor for surfactants using LC-ESI-TofMS. We are interested in learning about your surfactant application or problem.

Surfactants are everywhere! They are a profoundly useful group of chemicals due to their amphiphilicity and resulting surface activity. There are a multitude of different chemical entities comprising the available surfactants/detergents. There are also products that are a complex mixture of several surfactants sometimes of quite different chemistries, e.g. LiquinoxR. Besides being great in cleaning agents (detergents), surfactants can also have uses in formulations where components of different polarities need to be "compatibilized".

Simply put, surfactants are used wherever solubilization or "compatibilization" are required. Surfactants are used across the board in industries such as cosmetics, food, cell culture, pharmaceutical formulation and processing and OTC drugs such as eye drops. In manufacturing operations, they mostly show up in cleaners: pre-cleaning of packaging components, cleaning of process equipment, line clearances, wipe-down of cleanroom and clean bench surfaces, and final cleaning of biomedical devices and long-term implantables.

Obviously, surfactants are irreplaceable - manufacturing and quality engineers cannot do without them. However, they can wreak havoc if they get out of control. Surfactants can be ocular irritants even at low concentrations. Residual surfactants on surfaces can interfere with adhesion in bonding processes or interfere with coating deposition and adherence. Surfactant contaminants in product can interfere with their functionality and long-term stability, e.g., coatings.

Modern LC/MS methods can detect surfactants at very low concentrations and assure that they are being kept under control - in fact, LC/MS techniques are uniquely suited because of the aqueous nature of most surfactant solutions and also because these molecules ionize readily in the electrospray ion sources commonly used in LC/MS systems. In addition, surfactants give very characteristic mass spectral patterns that readily enable differentiation between them (link to Fingerprinting and Equivalence Testing).

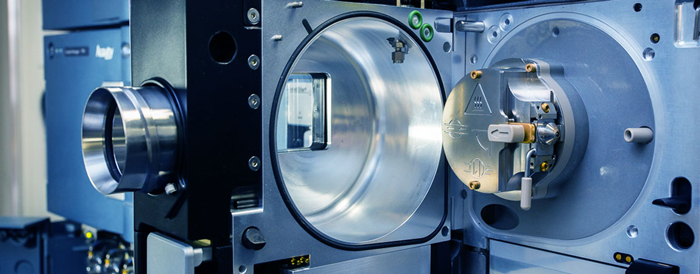

LC/MS provide the sensitivity and selectivity to identify and quantitate sub-ppm levels of surfactants in solutions. With Mass Spec Lab's Acquity UPLC and Xevo G2-S QTof MS and our SEAC (Surfactant Express Analysis) methodology, we are able to provide an economic testing option so that you can proactively avoid potential product and process problems, possible line shut-downs, or recalls. Let us know if you would like to learn more about SEAC testing.

Comments (1)